POLYETHYLENE

Polyethylene is a member of the polyolefin family which also includes polypropylene. This group of materials is the most widely used accounting for over half of worldwide thermoplastic consumption.

Due to the different properties and applications the different variations of polyethylene will be described separately – High Density (HDPE), Low Density (LDPE) and Linear Low Density (LLDPE).

Please Note: This page is for information purposes only. Rutland Plastics is an Injection Moulder and does not supply polymers.

HIGH DENSITY POLYETHYLENE (HDPE) PROPERTIES

PROPERTIES

Compared to LDPE, HDPE has greater rigidity, hardness, heat distortion temperature (HDT) and chemical resistance but a lower impact strength. It has better low temperature properties than polypropylene homopolymer but is not as flexible or as hard. As with polypropylene the material is resistant to boiling water.

COLOURING

HDPE is translucent white in its natural condition and is therefore easy to colour. UV stability is satisfactory although if the material is to have long term exposure then UV stabilisers will need to be used for added protection.

Finishing

As this material has a waxy surface it is not suited to joining by using adhesives. Therefore, other methods of joining, such as snap-fits or welding, need to be considered. Machining can be difficult but is possible.

CHEMICAL RESISTANCE

| Mineral Acids (dilute) | Excellent |

| Mineral Acids (concentrated) | Fair |

| Alkali | Excellent |

| Alcohol | Good |

| Ketone | Good |

| Aromatic Hydrocarbon | Poor |

| Chlorinated Hydrocarbon | Poor |

| Detergents | Fair |

| Oils, Greases | Excellent |

POLYETHYLENE USE

| Bottles | 29.6% |

| Films | 17.3% |

| Tube | 13.3% |

| Large Containers | 12.8% |

| Injection Moulded Packaging | 6.2% |

| Crates | 4.0% |

| Appliances | 1.3% |

| Toys | 1.2% |

APPLICATIONS

As HDPE retains its strength and stiffness at low temperatures it is widely used in the manufacture of containers used in refrigeration, bottle crates or food storage boxes. Also widely used in housewares and dustbins. The automotive industry has used HDPE for fuel tanks.

LOW DENSITY POLYETHYLENE (LDPE) & LINEAR LOW DENSITY POLYETHYLENE (LLDPE)

PROPERTIES

LDPE material is tough but has only moderate tensile strength and suffers from creep. It has excellent impact resistance, chemical resistance and insulation properties.

LLDPE was developed in the 1950’s and is a copolymer of ethylene and a small percentage of octane or butane. The effect is to give better mechanical properties than LDPE at both low and high temperatures. It can also be stronger and tougher than LDPE.

COLOURING

Both materials are translucent white in their natural condition and are therefore easy to colour, transparent mouldings are not possible. Both materials have poor UV stability so UV stabilisers or carbon black will need to be used.

Finishing

As this material has a waxy surface it is not suited to joining by using adhesives. Therefore, other methods of joining, such as snap-fits or welding, need to be considered. Machining can be difficult but is possible.

CHEMICAL RESISTANCE

| Mineral Acids (dilute) | Excellent |

| Mineral Acids (concentrated) | Good |

| Alkali | Excellent |

| Alcohol | Good |

| Ketone | Good |

| Aromatic Hydrocarbon | Poor |

| Chlorinated Hydrocarbon | Poor |

| Detergents | Fair |

| Oils, Greases | Good |

POLYETHYLENE USE

| Film Sheeting | 74.3% |

| Extrusion Coating | 6.9% |

| Injection Moulding | 5.7% |

| Wire/Cable | 3.7% |

| Blow Moulding | 2.1% |

| Pipe/Conduit | 1.9% |

| Others | 5.3% |

APPLICATIONS

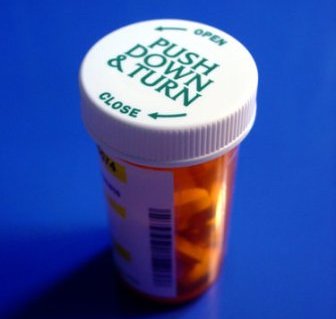

Due to the relative cheapness of LDPE it is widely used in packaging, for example lids and closures for bottles and other containers as well as bins, linen baskets, etc.

LLDPE is widely used in film manufacture. Injection mouldings can have high gloss and good impact strength. Again this material can be used for closures, especially screw caps that require a good torque retention. It may also be used for containers used in cold rooms and high quality housewares and toys.