Understanding Injection Moulding Costs in the UK

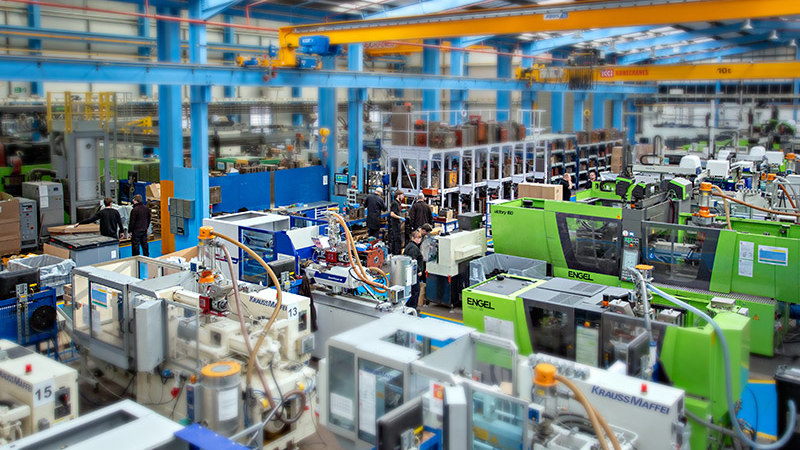

Rutland Plastics provides transparent pricing for tooling and production, helping businesses plan effectively. With over 70 years of expertise, we deliver cost-efficient injection moulding solutions that maximise long-term value.

Introduction

One of the most common questions asked about injection moulding is: “How much does it cost?” The answer depends on several factors, such as design complexity, material choice, order volume, and tooling requirements. While the initial outlay for the mould tool can be significant, the process becomes highly cost-effective for medium to large production runs.

At Rutland Plastics, we break down costs clearly so you understand both the upfront investment and the savings that come with volume production.

The Basics of Injection Moulding Costs

The cost of injection moulding in the UK can be divided into two parts:

Tooling costs – the one-off price of creating a mould tool.

Production costs – the cost of manufacturing each part once the tool is complete.

This structure means that while the first part is more expensive, costs quickly fall as volumes increase.

Step-by-Step Breakdown of Costs

A simple single-cavity tool may cost around £10,000, while larger, multi-cavity, or complex tools can exceed £100,000.

Thermoplastics vary in price; commodity plastics are more affordable, while engineering grades cost more.

Larger machines with higher tonnage require more energy and longer cycle times, increasing costs.

Skilled operators, machine programming, and quality inspections contribute to cost.

The higher the production run, the lower the cost per part due to economies of scale.

Why Injection Moulding is Cost-Effective

Despite the upfront tooling cost, injection moulding is one of the most economical ways to produce plastic parts at volume. Once the mould tool has been manufactured, each production cycle is fast, waste is low, and per-unit costs decrease significantly.

The Role of the Mould Tool in Cost

The mould tool is the single largest investment in injection moulding. However, its design and durability directly influence long-term savings. A well-designed tool:

- Improves efficiency and reduces cycle times.

- Produces parts with fewer defects, minimising rework.

- Lasts for hundreds of thousands—or even millions—of cycles.

- Reduces overall per-unit costs across the lifespan of a project.

At Rutland Plastics, we engineer moulds with long-term performance in mind, protecting your investment.

Materials and Their Impact on Price

Thermoplastics material choice has a significant effect on cost. Examples include:

Affordable and widely used.

Higher cost but stronger and impact-resistant.

Transparent, heat-resistant, more expensive.

Durable engineering plastics, higher price.

Flame-retardant, UV-stabilised, or medical grades can add to cost.

Practical Example

Consider a company needing an electronic housing. A tool costing £10,000 may produce the first 1,000 units at a few pounds each. However, at 100,000 units, the cost per part could drop to just pennies. This scalability is why injection moulding is ideal for businesses aiming for mass production.

Advantages Over Alternative Processes

Compared to 3D printing or machining, injection moulding is more cost-efficient at scale. While 3D printing may be cheaper for one-offs or prototypes, it cannot compete with the low per-part cost achieved in injection moulding once volume production begins.

Conclusion

Injection moulding costs in the UK vary depending on tooling complexity, materials, and order volumes. While initial mould tooling may be expensive, the long-term benefits—low per-part costs, scalability, and durability—make it a smart investment for businesses.

Rutland Plastics provides detailed cost breakdowns tailored to each project, ensuring you have clarity and confidence before production begins.

FAQs – Injection Moulding Costs in the UK

Factors include part size, material, machine time, cycle duration, and production volume.

A simple tool may start around £10,000, while larger or more complex tools can exceed £100,000.

Yes, for medium to high volumes. For very small runs, 3D printing or machining may be cheaper.

Yes. Commodity plastics are cheaper, while engineering grades cost more.

Share your CAD file, part specifications, and volume requirements with Rutland Plastics, and we will provide a transparent, tailored quote.