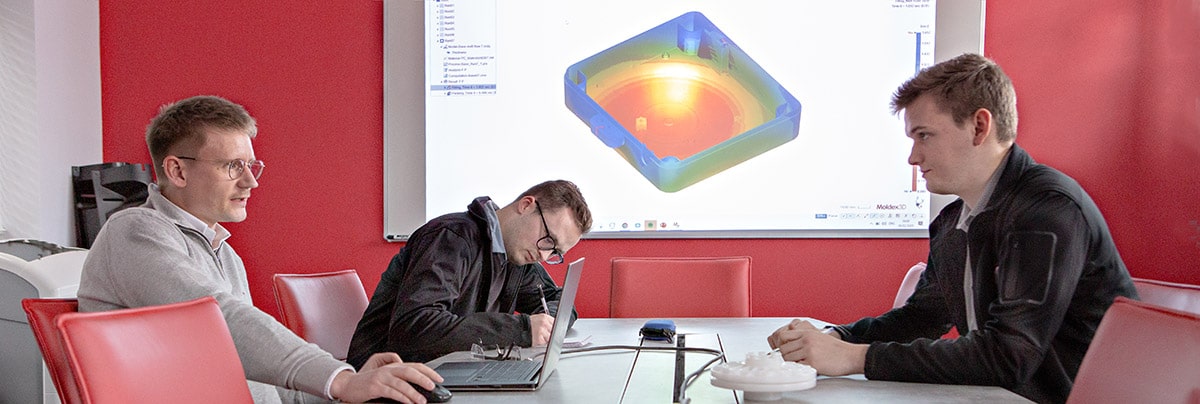

EXPERTS AT VERIFYING DESIGNS

Free advice and design support are offered to ensure your part design is optimised for injection moulding.

SPECIALISTS IN MOULD TOOLS

Free advice and design support are offered to ensure your design part is optimised for injection moulding.

SUPPORT WITH EXTRA CAPACITY WHEN YOU NEED IT

If you require extra capacity to grow your business we can help

HELPING YOU WHATEVER YOUR REQUIREMENTS.

THE UK’S LEADING PLASTIC INJECTION MOULDERS AND WINNER OF PROCESSOR OF THE YEAR.

Offering you a full range of plastic injection moulding services from design, including mouldflow, prototyping and mould making to injection moulding and a wide range of additional services such as machining and assembly.

MANAGEMENT

EXPERTISE

MANUFACTURE

EXPERIENCE

OUR SERVICES

You have an idea for a product or component but you do not yet have it fully developed. Not to worry.

We can work with you to take just an idea or sketch through to a finished product.

As our customer. your plastic injection mouldings will be manufactured using the most cost effective production methods.

Our extensive range of state of the art injection...

Whether it is low volume or pre-production tooling or even high speed, multi-cavity stack tools, we are able to specify and manufacture the most appropriate mould tools for our customers.

Plastic injection mouldings often need to be machined or assembled with other components. We have the expertise, flexibility and facilities to add the finishing touches and additional services required. This includes sonic welding, machining, gluing and multi-component assembly.

HELPING YOU WHATEVER YOUR REQUIREMENTS.

OUR APPROACH TO

SUSTAINABILITY AND CSR

In all business activities, we give consideration to our immediate community location, the wider environment and its natural resources. We manage our production processes with careful concern for the environment.

CASE STUDY

INDUCTION TECHNOLOGY

GROUP

“Rutland Plastics have provided support and expertise throughout the whole design and manufacturing process and it’s great to work with a team who share the same values as us".

RICHARD CLEWS, ITG.

ITG (Induction Technology Group) are manufacturers of high performance air filters for motorsport and road car applications. Rutland Plastics has worked closely with ITG for some time manufacturing various different products.

CASE STUDY

EPICOR ADVANCED MES

CASE STUDY

MADE SMARTER

360 FACTORY TOUR

TAKE A TOUR AROUND OUR FACTORY

Offering you a full range of plastic injection moulding services from design, including mouldflow, prototyping and mould making to injection moulding and a wide range of additional services such as machining and assembly.