LIQUID CRYSTAL POLYMERS (LCPs)

Liquid crystalline polymers (LCPs) are a special type of thermoplastics that exhibit properties between highly ordered solid crystalline materials and amorphous disordered liquids over a well defined temperature range

For several years now there has been a movement to replace metal with plastic in many applications. This has been driven by a need to achieve cost and weight savings but using plastics has also meant a wide range of design options has become available.

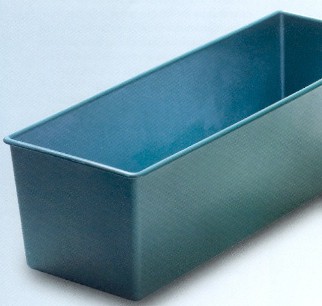

So, what about ovenware? The material that is used in this application is Liquid Crystal Polymer (LCP), and in particular Vectra® from Celanese. This material has traditionally been used in small components in products such as mobile phones, hearing aids and sensors for vehicles.

LC polymers are much more expensive than standard thermoplastics but have excellent mechanical and electrical properties and outstanding chemical resistance. They are used for very demanding applications in many industries. Examples include ultra-high-strength and lightweight fibres and cables, bulletproof vests, tennis strings, hockey sticks (as a composite), snowboards, tire reinforcement, jet engine enclosures, brake and transmission friction parts, and gaskets.

LC polymers are also widely used as functional materials in all kinds of optic and optoelectronic devices because their anisotropic material properties such as refractive index, birefringence, selective light reflection and transmittance, colour characteristics are tunable by temperature, mechanical stress, and electromagnetic radiation and fields. Important applications include temperature-sensing, data storage, display technology, telecommunication and numerous other optic and optoelectronic products.