POLYSTYRENE

There are two major types of polystyrene – General Purpose (GPPS) and High Impact (HIPS). As the properties and applications vary they will be dealt with separately.

Please Note: This page is for information purposes only. Rutland Plastics is an Injection Moulder and does not supply polymers.

GENERAL PURPOSE POLYSTYRENE (GPPS)

PROPERTIES

GPPS is a low cost hard, rigid material with high gloss and transparency. However, the material is brittle, burns easily and deteriorates with prolonged exposure to sunlight or fluorescent lighting.

COLOURING

GPPS is crystal clear which means a wide range of colours is possible. The material readily attracts dust so many grades have an antistatic additive. Because of its poor UV light resistance stabilisers are required for any product requiring a prolonged use.

Finishing

GPPS is easily bonded to itself by the use of solvents, or other materials by the use of impact adhesives. Polystyrene does not machine well, and drilling or tapping to produce a thread may prove difficult so inserts are generally used – either moulded in or post moulding ultrasonically or heat staked.

Mouldings can be decorated using silk screen printing, hot foiling, vacuum metallising and painting.

CHEMICAL RESISTANCE

| Mineral Acids (dilute) | Good |

| Mineral Acids (concentrated) | Good |

| Alkali | Good |

| Alcohol | Good |

| Ketone | Poor |

| Aromatic Hydrocarbon | Poor |

| Chlorinated Hydrocarbon | Poor |

| Detergents | Fair |

| Oils, Greases | Fair |

APPLICATIONS

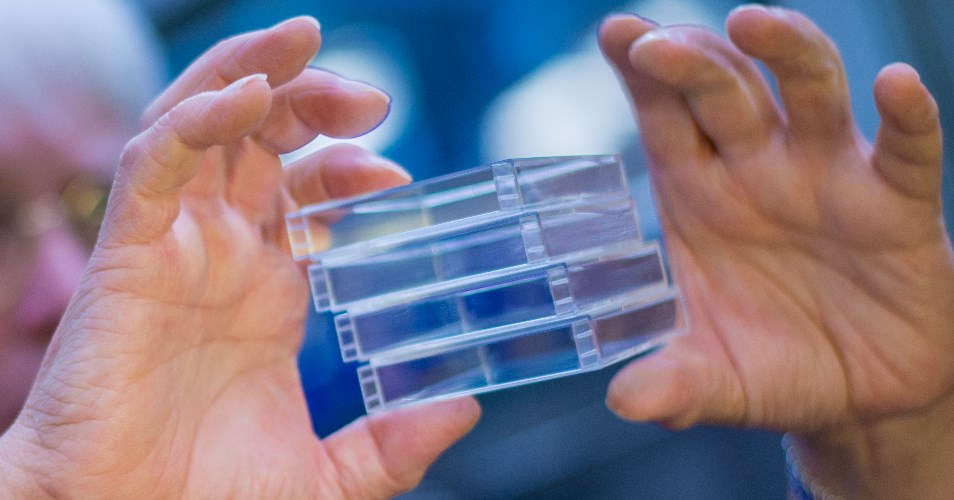

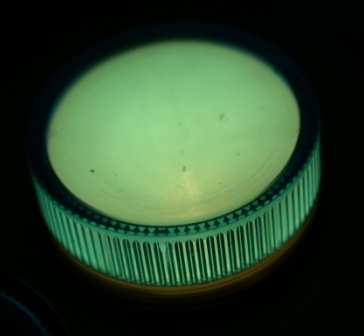

Low cost mouldings requiring a combination of colour, clarity and stiffness will be manufactured in GPPS. Typically toys, disposable tumblers, containers and some light diffusers when a suitable stabiliser is added.

HIGH IMPACT POLYSTYRENE (HIPS)

PROPERTIES

Higher impact strength is achieved by polymerizing with a small amount of rubber. However, the tensile strength, stiffness and hardness are lower than for GPPS as a result. There is also some loss of clarity and surface gloss.

COLOURING

Although HIPS is translucent rather than crystal clear a wide range of colours is possible. As with GPPS resistance to light is poor so stabilisers are required for any product requiring a prolonged use.

Finishing

HIPS can be machined more readily than GPPS. Components are often lacquered to improve weathering resistance and for decorative effects. Can be decorated in a variety of ways as with GPPS.

CHEMICAL RESISTANCE

| Mineral Acids (dilute) | Good |

| Mineral Acids (concentrated) | Fair |

| Alkali | Good |

| Alcohol | Fair |

| Ketone | Poor |

| Aromatic Hydrocarbon | Poor |

| Chlorinated Hydrocarbon | Poor |

| Detergents | Fair |

| Oils, Greases | Fair |

POLYSTYRENE USE

| Packaging | 44.0% |

| Appliances | 14.1% |

| Housewares | 9.5% |

| Furniture | 5.5% |

| Refrigerators | 5.2% |

| Toys | 2.7% |

| Shoe Heels | 1.0% |

| Automotive | 0.5% |

| Other | 17.5% |

APPLICATIONS

This material is used where a certain impact resistance is required. Used for household appliances, toys, disposable cups, etc.