POLYMER MELT FLOW

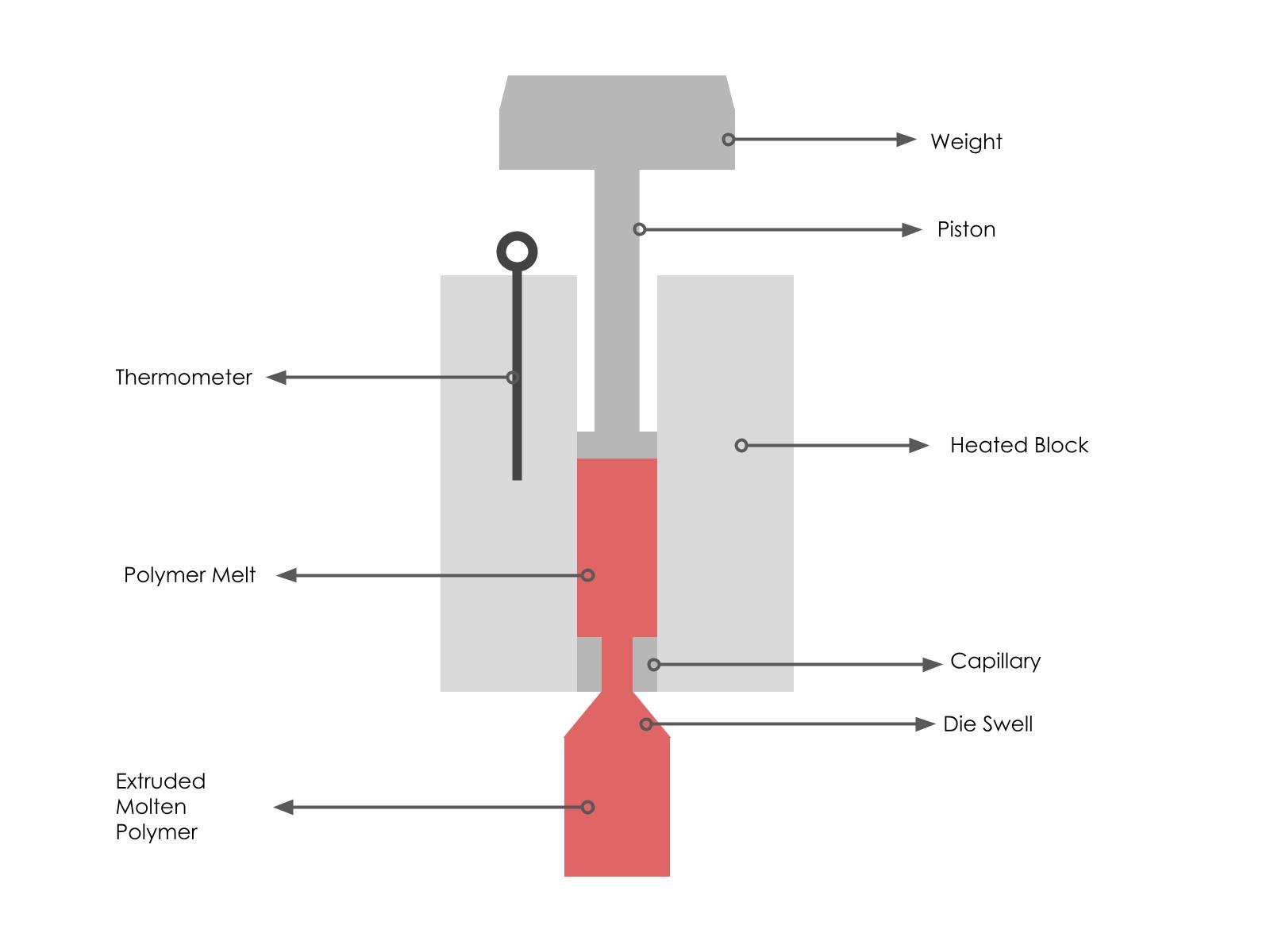

The Melt Flow Rate (MFR) or Melt Volume-Flow Rate (MVR) test measures the flow of a molten polymer under specific temperature and load conditions.

The material is placed in the cylinder and preheated for several minutes. The weighted piston is placed on top of the molten polymer and this forces the polymer through a 2mm die. The time for the test ranges from 15 seconds to 6 minutes and the weight on the top can be 1.2kgs, 5kgs or 10kgs. Temperatures also vary – 220˚C, 250˚C and 300˚C.

The amount of polymer extruded after the specified time is weighed and converted to the number of grams that would have been extruded in 10 minutes. The MFR is expressed in grams per reference time.

As a rule, an easy-flowing grade of material might be selected if there is a long flow length, thin walled section or a smooth surface required. However, the figures given on datasheets can only be a guide as various conditions will affect the flow rate.

A high viscosity grade should be selected if the parts are likely to be subjected to severe mechanical stresses; this is because as a general rule high viscosity grades tend to be tougher, have improved heat resistance and overall better mechanical properties.

ASTM D1238

| Procedure | Description |

|---|---|

| A | Manual Operation |

| B | Automatically Timed Flow Rate Measurement |

| C | Automatically Timed Flow Rate Measurement for High Flow Rate Polyolefins Using Half-Height, Half Diameter Die |

ISO 1133

| Procedure | Description |

| A | Manual Testing |

| B | Automated Testing |

REPORTING

The testing conditions are most commonly reported as temperature/load (i.e. 190°C/2.16 kg). Occasionally test conditions are represented by a letter code. These letter codes are described below.

| Letter Code | Temperature (°C) | Load (kg) |

|---|---|---|

| A | 250 | 2.16 |

| B | 150 | 2.16 |

| D | 190 | 2.16 |

| E | 190 | 0.325 |

| F | 190 | 10.00 |

| G | 190 | 21.60 |

| H | 200 | 5.00 |

| M | 230 | 2.16 |

| N | 230 | 3.80 |

| S | 280 | 2.16 |

| T | 190 | 5.00 |

| U | 220 | 10.00 |

| W | 300 | 1.20 |

| Z | 125 | 0.325 |