REACTION INJECTION MOULDING (RIM)

Please Note: This page is for information purposes only. Rutland Plastics is an Injection Moulder and does not offer RIM moulding services.

PROCESS

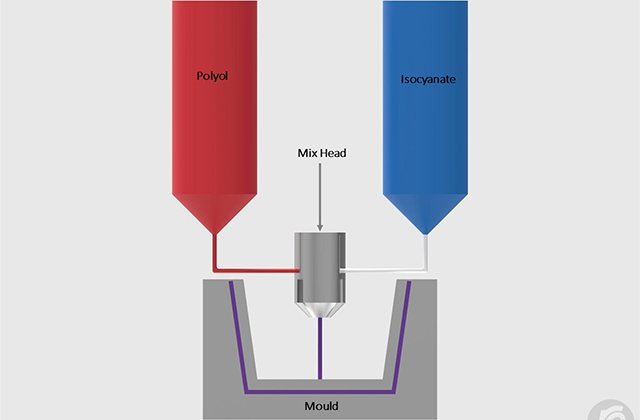

This is a form of injection moulding that produces components with a honeycomb like centre. It is a cold injection process that does not require pre-heating of moulds or post curing of parts. Two materials are mixed prior to injection; these materials react in the mould to form a solid moulding.

The low pressure process can produce large mouldings – up to 40kgs and in excess of 1m square with sections of 5mm-15mm. The resulting components have a high level of stiffness.

MATERIALS

This process uses a fast acting polyurethane resin.

APPLICATIONS

Products manufactured using this process include:

- Business machine housings

- Point of sale display components

- Containers

- Pallets

- Office furniture

- Sporting goods

- Automotive

- parts

ADVANTAGES

- Low pressure mouldings mean the mould tools can be manufactured from silicone, resin, modelboard or aluminium resulting in cheaper tooling costs

- Fast tool manufacture

- High impact strength and dimensional stability

DISADVANTAGES

- Parts are more expensive as the surface finish is generally poor needing filling, sanding and painting. Generally a textured finish is used

- Slow cycle times

- Expensive raw materials