COST CONSIDERATION IN DESIGN

There are two areas of cost consideration in designing for injection moulding: the design of the part to minimise production costs and the design of the part to minimise tooling costs. Here we consider these two aspects of design.

Other technical pages to read:

Design for Mouldability

Design for Recyclability

Design for Time

Design Summary

PRODUCT CONSIDERATION

Injection moulding is a heat process and plastics are poor conductors of heat, that is to say it takes a relatively long time for plastic parts to cool down. With this in mind the aim should be to keep sections of parts as thin as possible, this will not only mean shorter moulding cycle times but also less material content.

STRENGTH

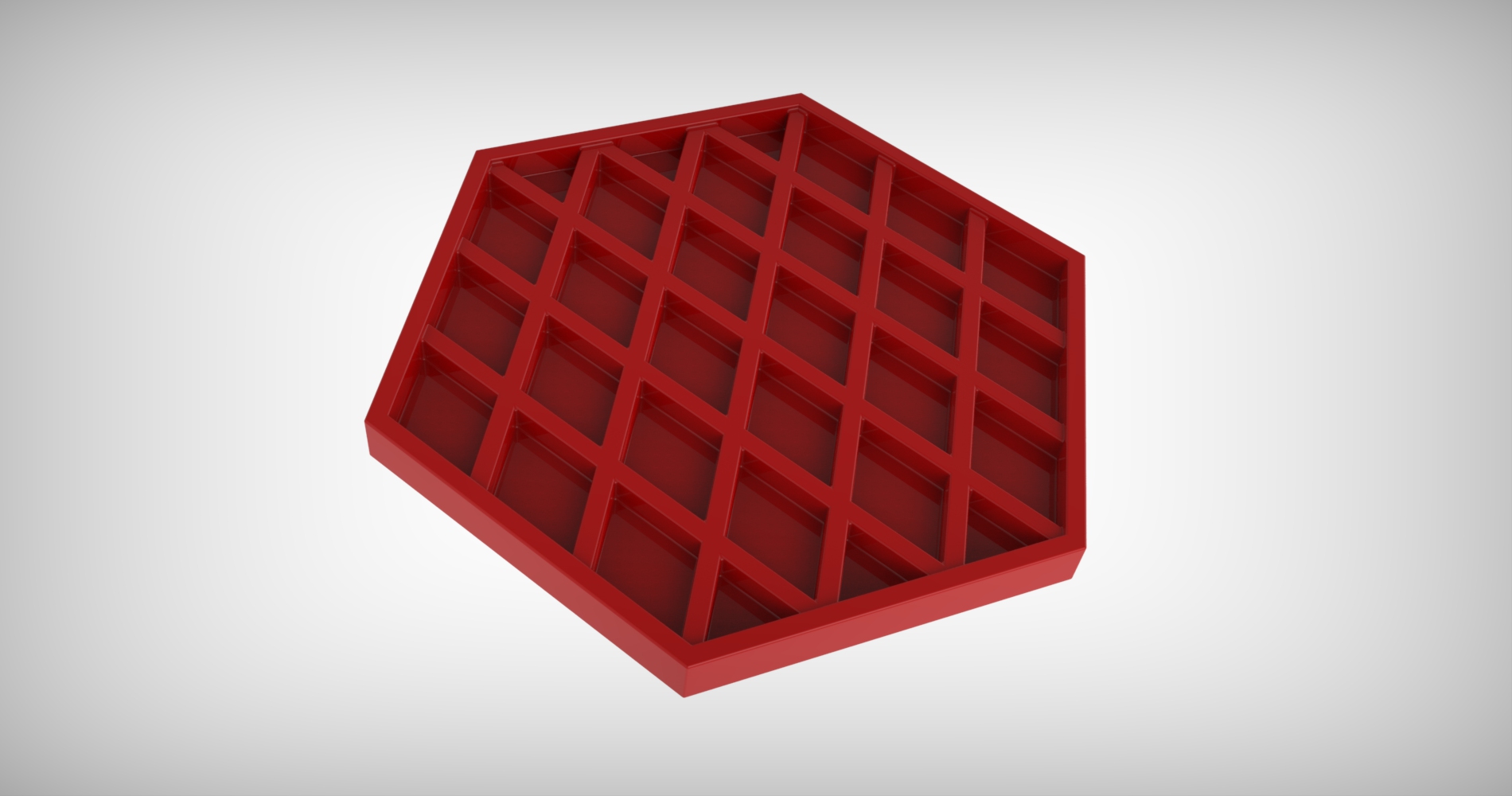

If the part needs some strength this can be achieved by the addition of ribs rather than thickening of the section. With plastics, thicker sections do not necessarily mean stronger parts, in some instances beyond a certain thickness the part can become more brittle due to the resulting lack of flex.

MATERIAL

Another cost consideration is choice of material type and grade. Thermoplastics can range in price from just over £1 per kg for basic polyolefins up to £35 per kg and beyond for PEEK and other specialised polymers. By designing strength into a part it may be possible to use a cheaper material but sometimes the reverse can be true and advice should be sought from the moulder.

The price of polymers is also governed to a certain extent by the amount purchased so some benefit may be gained by using a grade already used by the moulder. Be guided by the moulder rather than sticking rigidly to a specified grade.

ELIMINATE ASSEMBLY

If a number of parts are required, and especially when converting from metal or a different production method, look at the possibilities of combining two or more parts into a single moulding so eliminating assembly. It is often possible to produce complex single mouldings that would not be possible with a different method of production. In a similar vein, where assembly is required every effort should be made to make this as simple as possible with the use of snap-fits, for example.

TOOLING CONSIDERATIONS

COMBINING PARTS

Injection mould tooling is relatively expensive but it is not always correct to assume that it is only suited to long production runs. If it is possible to combine a number of parts into a single moulding, for example, then the cost of assembly and possible other ancillary parts can be saved making shorter production runs economical.

Rutland Plastics was approached to replace a number of relatively low volume polyurethane foam mouldings produced by reaction injection moulding (RIM). These parts required finishing, including painting, as well as assembly operations. One of these parts was a base that contained a filter. The original part had two steel runners secured by 3 screws each to hold the filter, along with 2 aluminium baffles that were also attached by screws. The final injection moulding had moulded in runners and baffles so eliminating not just the costly parts but also the assembly operation. Although the resulting mould tool was complex and therefore expensive the payback was less than 2 years on just 400 bases per month.

KEEP IT SIMPLE

The simpler the mould tool the lower the cost. If possible design plastics parts to avoid holes in side walls of parts, undercuts and other complex features. The mould tool can then be what is referred to as straight open and close. If the part does need side holes, for example, then these can either be moulded in which would require side movements in the mould tool, or a secondary operation will be necessary. Which approach is adopted will depend on anticipated quantities of the part – the higher the number of parts required the more economical it is to have the features produced by the mould tool rather than as a secondary operation.

The same rule applies to threads. Internal threads can of course be tapped afterwards but the usual method is to have them moulded in. This can be achieved in two ways, either with hand loaded cores or with auto unscrewing in the mould tool. The former requires operator intervention during the moulding process so adding to the part cost whereas the latter means the mould tool can be run fully automatically but will mean a higher tooling cost at the outset.

MULTIPLES

To reduce both total tooling and part costs where a number of similar parts are required in equal quantities and in the same material, it may be possible to produce a family tool, i.e. all the parts moulded in a single cycle from a single tool. Also, where large quantities of a part are required, a multiple cavity tool could be used, i.e. two or more of the same part produced in a single cycle. Although the tooling cost would be higher than for a single impression tool, the part price will be lower so making it cost effective. The moulder can advise on the optimum configuration.

CONCLUSION

There are a number of factors that impact upon part and tooling cost consideration: material selection, section of part, complexity of design, etc. What is certain is that the further down the design/production cycle you are the more costly any alterations become. Therefore, it is advisable to get the initial design right for injection moulding and to this end you should involve your injection moulder at the very early stages of the project to ensure correct design and material selection for the given application. Rutland Plastics experienced technical staff are here to advise you and offer support on your project from initial concept right through to delivery of the finished product.

FURTHER READING OR LINKS TO ALL GUIDES?

- Design Guide

- Design Development

- Design For Appearance

- Design For Assembly 1

- Design For Assembly 2

- Design For Assembly 3

- Design For Cost Consideration

- Design For Economy

- Design For Mouldability 1

- Design For Mouldability 2

- Design For Mouldability 3

- Design For Precision

- Design For Recyclability

- Design For Stiffness

- Design For Strength

- Design For Time

- Design Summary

- Flame Retardancy

- Flexibility

Free design guide

"*" indicates required fields