DESIGN FOR RECYCLABILITY

Environmental legislation is increasingly focusing on the recyclability of products. This is already in evidence in the automotive and consumer goods industries and is likely to become increasingly prevalent. Plastics are a particular target because of the disposal problems associated with them coupled with the fact that the vast majority of plastic materials can be relatively easily recycled although cost is currently prohibitive in most cases (material considerations include Bioplastics).

This article is part of a series:

Design for Appearance

Design for Economy

Design for Recyclability

Design for Time

Design Summary

MAKING RECYCLING EASIER

Although functionality is still the primary consideration in design, designers now have a responsibility to design with the economic use of materials and end of life recyclability in mind.

The following guidelines should be followed for products designed to be recyclable:

- Avoid using metal inserts as they are difficult to separate and make recycling uneconomic

- Avoid using self-tapping screws and use snap-fit wherever practical

- Avoid bonding with polyester and polyurethane based adhesives. If unavoidable then use ‘break-out’ facilities to make for easy separation of the bonded section. (Break-outs could also be used for removing metal parts if practicable)

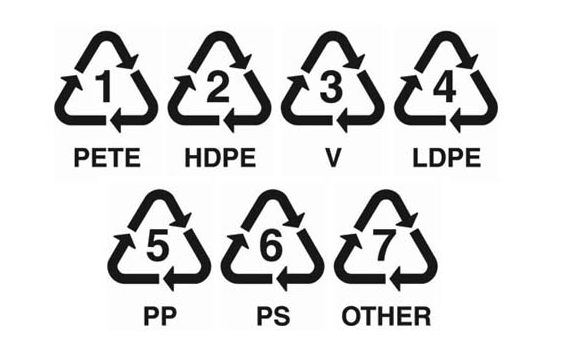

- Where possible make components from the same material and grade. Where different materials are used clearly mark each part with material identification for ease of sorting

- Avoid using decorative paints, lacquers and protective coatings

- When printing or hot-foil decoration is used, easy to remove secondary moulding can be used as the base

- Reduce the amount of material. Gas assisted injection moulding (GAIM) can be used to hollow out thick sections. Another option is to reduce the density of the material through the use of chemical foaming agents

It is not always possible to use a single material as different components within a product or sub-assembly may have to perform different functions. This can add to the cost of recycling as the parts need to be sorted with the different materials clearly identified and separated.

FURTHER READING OR LINKS TO ALL GUIDES?

- Design Guide

- Design Development

- Design For Appearance

- Design For Assembly 1

- Design For Assembly 2

- Design For Assembly 3

- Design For Cost Consideration

- Design For Economy

- Design For Mouldability 1

- Design For Mouldability 2

- Design For Mouldability 3

- Design For Precision

- Design For Recyclability

- Design For Stiffness

- Design For Strength

- Design For Time

- Design Summary

- Flame Retardancy

- Flexibility

Free design guide

"*" indicates required fields